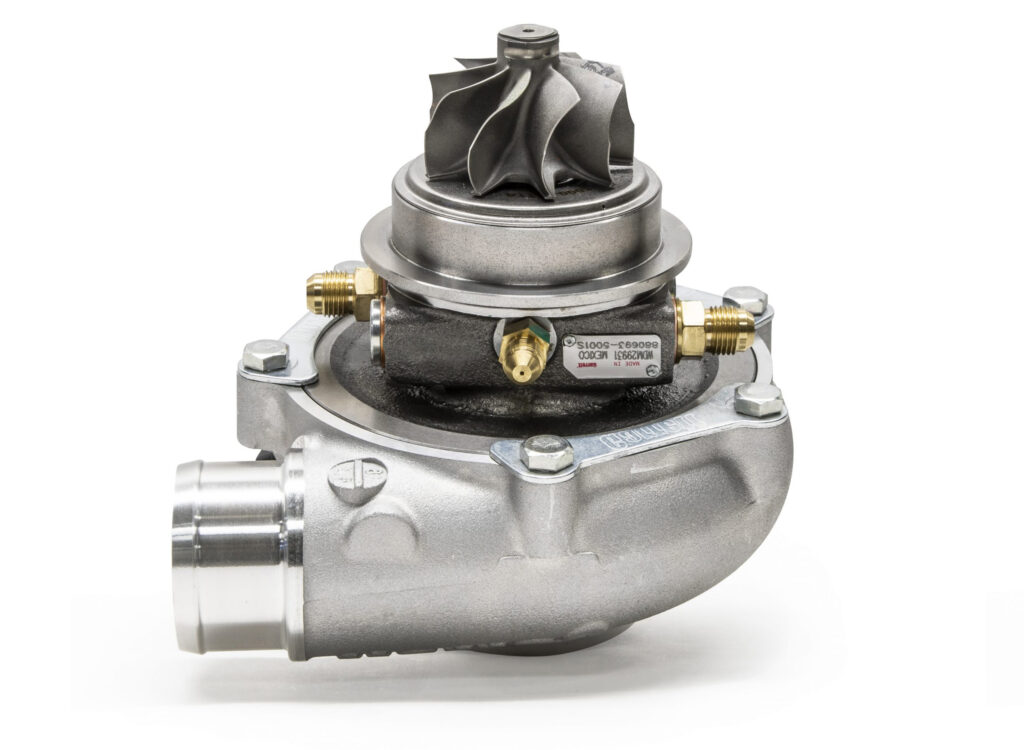

Garrett G35-900 Supercore, Reverse Rotation

$2,422.76

In Stock

California Residents: Prop 65 Warning

Additional information

| Weight | 30 lbs |

|---|---|

| Dimensions | 12 × 12 × 12 in |

CARB And / Or EPA Compliance Testing Not Completed

While we believe this product is either CARB EO exemption applicable, or complies with the EPA's Anti-Tampering Policy, we have not completed the required testing and administrative process at this time. This product is not available to purchase for emissions-controlled vehicles located within the state of California, or available to ship to California addresses, without a completed AMS Race Waiver form. International users outside of the United States should act in accordance with their local laws and regulations.

With 24 years of documented research and development in the forced induction field, AMS Performance has proven itself as the powerhouse in the automotive aftermarket. Our award winning performance systems are what all others are measured by.

The G-Series G35-900 reverse rotation turbochargers are compatible with 2.0L – 5.5L engine displacements and capable of producing 550-900 horsepower. G Series 35 turbochargers are smaller and outflow all comparable products on the market. New G Series 35 turbochargers have a larger trim compared to GTX models. Wheel trim is a ratio of the inducer to exducer of a compressor wheel and exducer to inducer of the turbine wheel. The larger the trim, the less difference you have between inducer and exducer.

G series reverse rotation turbochargers feature the latest innovations in turbocharger technology. Advanced compressor and turbine aero offer enthusiasts a wide range of performance boosting solutions for 2.0L – 5.5L engine platforms. Standard and reverse rotation options are offered with a variety of turbine housing configurations making it easy to select the right turbocharger for your application.

-

62mm turbocharger compressor wheel

-

New G Series compressor wheel aerodynamics

-

Fully machined speed sensor and pressure ports

-

Standard and reverse rotation configurations available

-

Oil restrictor and water fittings included with purchase

-

One piece center housing and backplate for increased durability

-

4 water jacket ports for customizable installation

-

Mar-M turbine wheel material rated up to 1050° C | 1922° F

Center Housing

A new one-piece center housing and backplate increase durability and product safety by reducing the number of failure points associated with the turbocharger. The center housing to turbine housing v-band connection allows for 360 degree orientation when installing with Garrett® non-wastegated turbine housings.

Four large water jacket ports increase cooling capacity and allow enthusiasts to customize water line routing to help improve the installation process. The turbocharger comes with two -6AN water fittings and two plugs. *Recommended to install waterlines on opposite sides of the housing.

A single stage oil passage directs pressurized oil to the new oil cavity ensuring proper bearing lubrication at both sides of the cartridge.

Each turbocharger includes (1) -4AN oil restrictor fitting with a 1mm orifice to provide the turbo with the recommended 40psi of oil pressure.

Rotating Group- twin piston rings

A shorter bearing cartridge allows us to incorporate twin piston rings on both sides of the shaft wheel assembly. This will reduce the likeliness of oil leakage at the seals from the center housing to the compressor and or turbine stage.

Turbine Wheel Aero

The turbine wheel features all new aerodynamics to improve flow and boost response. The new turbine wheel is made of Mar-M super alloy and is capable of handling exhaust gas temperatures up to 1050 degrees C.

The new turbine wheel flows 15-20% more than GTX and has peak efficiency of 74%.

Turbine Housings

All G Series Turbine housings are made from stainless steel to provide ultimate durability and temperature resistance up 1050 degrees C.

Internally wastegated housings are compact, efficient, and designed with maximum bypass port size to reduce boost creep and provide better boost control.

Turbine housings are available in a variety of wastegated and non-wastegated, open volute, T25 and Vband configurations so be sure to order the correct part for your application. *IWG housings are sold assembled as a full turbocharger, while non-wastegated turbine housings are available separately from the SuperCore (CHRA+compressor cover)